Trusted Quality

Policy and approach relating to quality

It is no exaggeration to say that quality assessments by customers determine the valuation of products and the brand value of a powertrain manufacturer. In the modern world of remarkable technological innovation, the level of quality sought by our customers is increasing more and more.

At a time when the structure of the global economy is changing greatly and urbanization is progressing in each region, needs with respect to mobility are also growing.

As an powertrain manufacturer, JATCO believes that in addition to fulfilling our mission of providing the abundance brought about by mobility to people throughout the world, we have a major responsibility to provide quality that satisfies our customers at all times.

JATCO understands quality to be an issue for the entire company; is continuing activities to provide superior quality in all of the situations involving the customers, from planning of the products to development, production, logistics, sales, after-sales service, etc.; and is aiming to be a company which is trusted by its customers.

Simply put, the word “quality” covers wide-ranging content. JATCO is collaborating across departments and regions to make company-wide efforts to provide superior quality in all situations involving our products, from the useability of the products themselves to the response when there is a defect in a product, etc.

Based on a philosophy centered on the customers, JATCO is making efforts for both “product quality” and “service quality” with the goal of “putting the opinions of our customers first and enhancing the quality of our products and services so that our customers will feel deep satisfaction, in order to ensure that they choose JATCO-made products for many years to come.”

The “product quality” of the products themselves is the fundamental quality that enables our customers to use the products comfortably and with peace of mind for a long time.

We aim for the provision of quality which can meet the expectations of our customers in all of the life cycle of the product, such as the “initial quality” of the product delivered to the customer and the “durable quality” felt when using a product for a long time, etc.

Furthermore, in “service quality,” the pursuit of quality in our responses to our customers, we carry out activities to make inspections and repairs easy to do at dealers.

In order to satisfy our customers in all of the processes, JATCO has introduced initiatives to incorporate the opinions of our customers and give feedback throughout the company.

Quality Policy

Management relating to quality

JATCO understands securing the safety of our customers and providing quality which satisfies them at all times to be important issues. In order to realize sustained growth as a trusted company, we have built systems to promote quality enhancement globally and all of our employees are working together on quality activities. We clearly stipulate and apply globally the responsible persons and processes for wide-ranging quality enhancement activities in a quality management system that is compliant with IATF 16949. Moreover, we revise manuals appropriately as necessary to ensure that this leads to the thorough implementation of quality management with respect to all of those quality items. Furthermore, we implement training every year regarding the guidelines for building and implementing a quality management system. All of our employees are required to take this training.

Note that regarding our production bases, all 13 bases have acquired IATF 16949 certification.

Management system relating to quality

In order to achieve the goal of becoming top level in quality, JATCO appoints a corporate officer dedicated to quality to the position of Chief Quality Officer. A Quality Committee chaired by the Chief Quality Officer meets every month, the officers of the respective divisions participate, and the committee promotes the quick solution of issues with product quality and service quality and also promotes quality improvement activities.

Furthermore, in order to realize the thorough implementation of compliance, we have built a monitoring and auditing system with a three-tiered structure and are making efforts to strengthen our auditing activities. In the first tier, the respective divisions implement monitoring with responsibility for compliance with laws and regulations and standards. In the second tier, the Corporate Quality Assurance Division implements audits concerning compliance with laws and regulations and standards. In the third tier, the Internal Audit Office carries out audits based on the fiscal year plan in accordance with the risks.

Quality enhancement initiatives

Reflection of the opinions of our customers in quality enhancement activities

In order to provide the value expected by our customers and respond quickly to the dissatisfaction, etc., felt by customers, we listen to all of the opinions from our customers and reflect them in all of our quality improvement activities, from development to servicing.

Quick responses to the opinions of our customers and timely information sharing

JATCO responds to inquiries and consultations from our customers through the automobile manufacturers.

Furthermore, we share the opinions of our customers in the market by posting them on the in-house intranet so that they can be viewed by our employees at any time.

Reflection of the opinions of our customers in our products and services

We have put in place mechanisms to reliably share the opinions of our customers in the market with all of our divisions including planning, development, production, sales, etc., and reflect the opinions in our products and services. Elements which make our customers feel dissatisfaction even though they are not malfunctions also influence the quality of the products. JATCO understands responding to the dissatisfaction of our customers to also be the subject of quality enhancement activities and is working on improvement.

The expected value that our customers require from our products differs depending on the customers' region, age, tastes, etc., and sometimes is also affected by market characteristics such as the degree of adoption of the product and the climate, etc. JATCO uses global design as its basic specifications while also responding in accordance to the needs of the regions.

The person who bears responsibility for this role is the Chief Quality Engineer (CQE). The CQE is involved from the planning stage to product creation and works on reducing the dissatisfaction of our customers and the number of defects.

We endeavor to extract the opinions of our customers from market information, etc., decide the order of priorities from the planning and development processes onward in order to consider response measures, and reflect the opinions in our products and services.

Initiatives to foster a customer perspective

We believe that it is important for each and every employee to take the perspective of our customers and work on their operations with an awareness of “realization of superior quality that continues to be trusted by customers” so we are promoting a variety of initiatives such as companywide training to foster good mindsets and initiatives to give our employees opportunities to encounter the opinions of our customers on a daily basis.

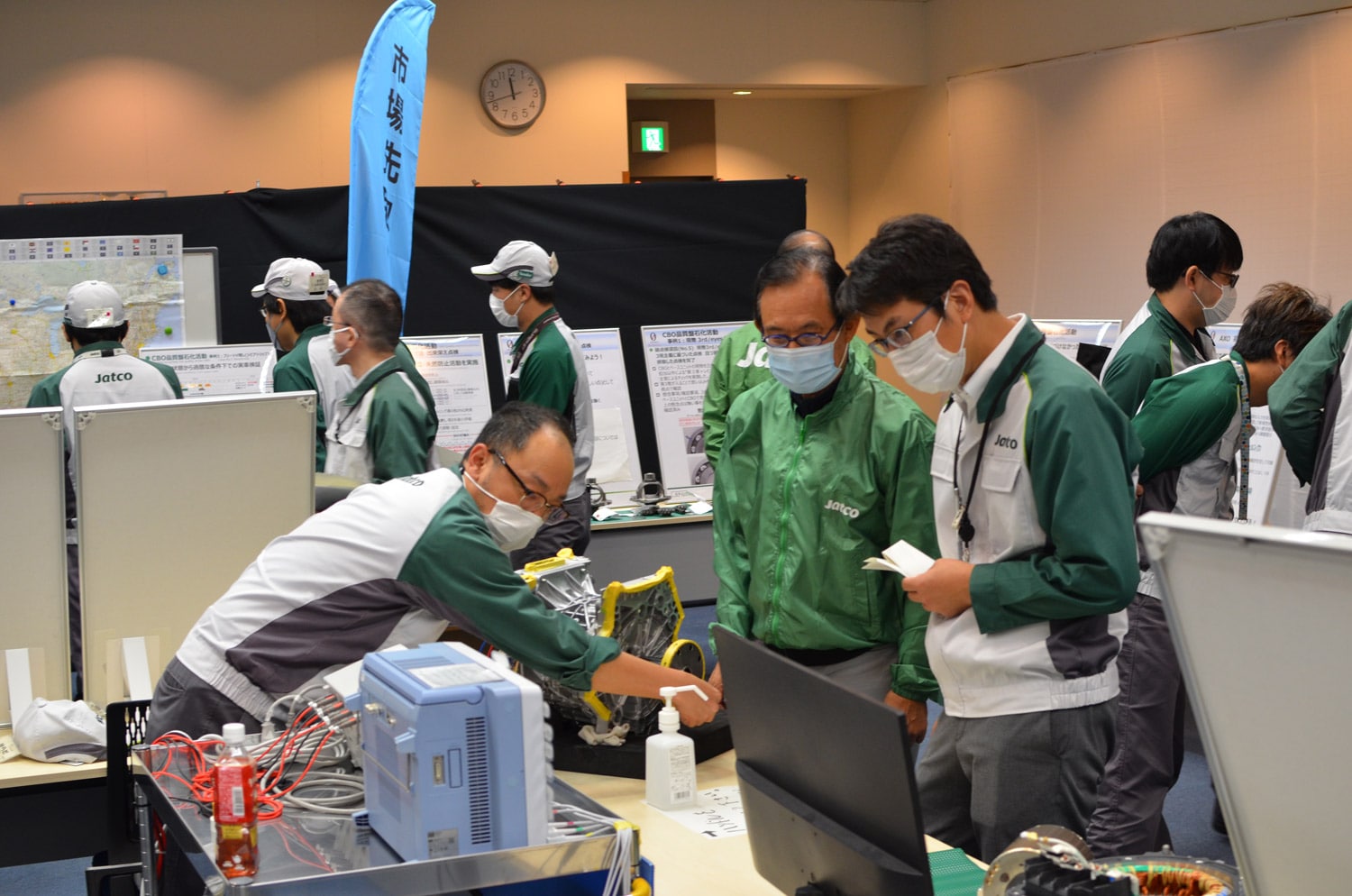

Furthermore, we have been holding the JATCO Quality Forum for our officers and employees since 2006. This forum introduces the current state of quality, the opinions of our customers in the market, improvement activities based on the opinions of our customers, and activities for the achievement of our goals, using panels, videos, and displays of actual components. It is jointly held by all of the divisions involved in development and services and in recent years hands-on events have been incorporated to encourage our employees to think and take action from a customer perspective.

Moreover, in order to reflect the opinions of our employees in quality enhancement activities, we have established opportunities for direct dialogues between officers and employees. In 2023, more than 2,500 people participated in these dialogues, which we held in Japan and overseas.

We are working to raise the importance of quality and awareness of our customers among our employees working globally.

Enhancement of “product quality”

“Product quality” is the fundamental quality that enables our customers to use the products comfortably and with peace of mind for a long time. For JATCO, which has carried forth Japanese “monozukuri,” “product quality” is the foundation which supports the sustainability of the company. We are endeavoring to think about quality from the customer perspective at all times, respond quickly when a defect occurs, and prevent recurrence of the defect. Furthermore, we are enhancing “product quality” to satisfy as many of our customers as possible, by reliably ascertaining the dissatisfactions of our customers and implementing countermeasure activities in all of our processes to eliminate them.

Market quality improvement activities

Initiatives for quick quality improvement in the market

JATCO has taken permanent countermeasures such as ascertaining the state of complaints and defects, through the automobile manufacturers, of sales companies and of customers who have entered the Customer Service Office, etc., sharing the information with the Development Department and the Production Department, and investigating the cause and considering countermeasures, etc., in order to encourage prevention of the spread of the defects.

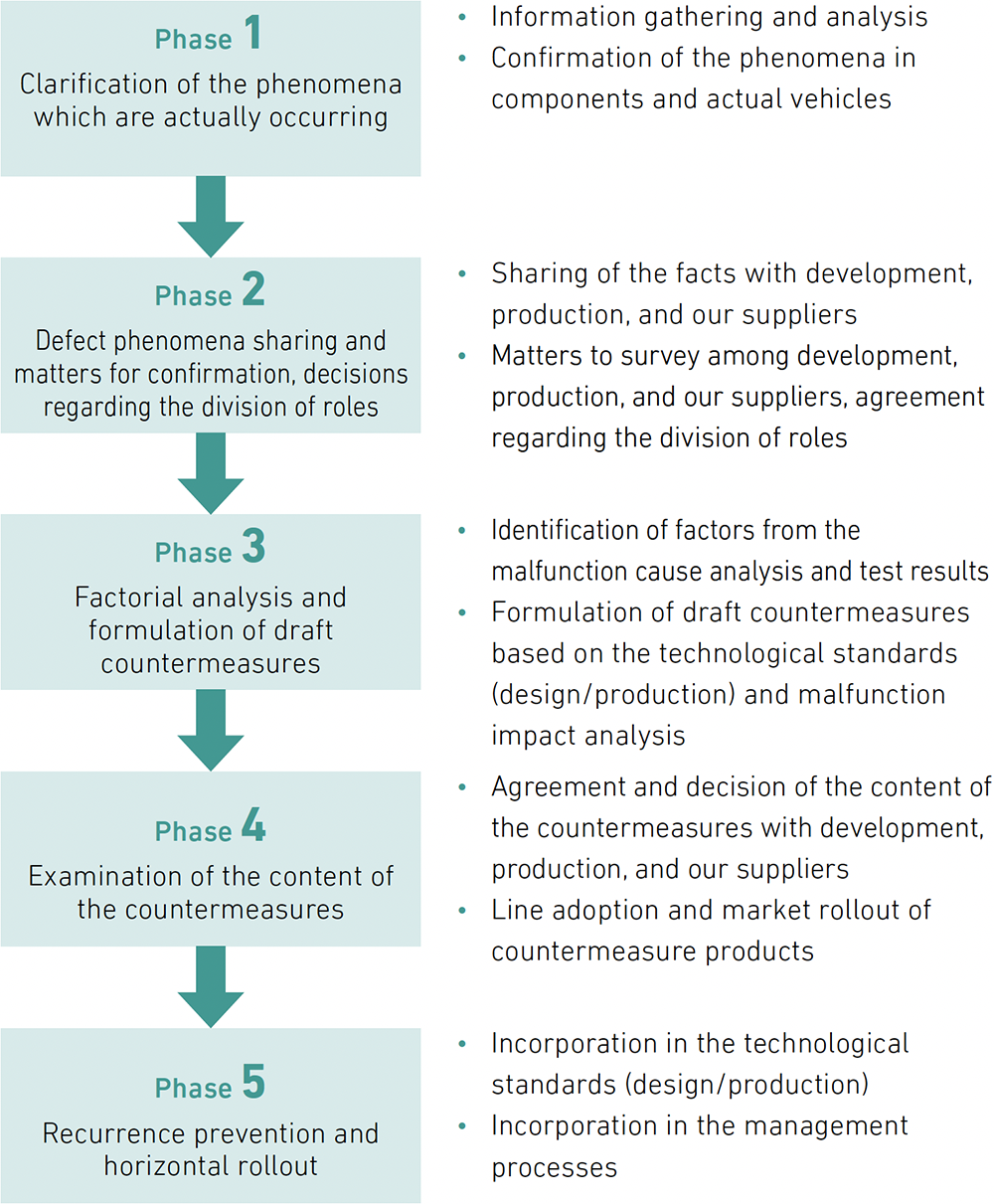

Furthermore, as a consequence of the corporate activities of JATCO expanding globally, there is a possibility that the complaints and defects could occur in regions around the world. In order to quickly analyze those kinds of defects and analyze the factors behind them locally, JATCO has established survey bases in seven locations: Japan, the United States, Europe, China, South Korea, Mexico, and Thailand. At these survey bases, we are implementing market quality survey and analysis activities divided into five phases.

The concept of market quality survey and analysis activities in five phases

Enhancement of initial quality

We are strengthening initiatives to deliver superior quality products to our customers. We confirm that quality has been improved for each process and visualize the risks which could possibly occur from the planning stage to consider measures to alleviate the risks. We are guaranteeing superior quality at the time of the launch of new products by implementing all of the processes using transparent judgments in this way.

Improvement of durable quality

In order to have our customers ride in comfort for a long time, we are promoting initiatives with respect to deterioration that occurs due to use over many years.

In order to reduce not only the defects which occur during the warranty period but even the defects which occur after the warranty period, JATCO recovers secondhand cars and components that were actually used by our customers to implement quality confirmation, obtain and analyze a variety of data for utilization in the early detection of defects, etc., and strengthen the development of technologies which are resistant to deterioration.

Regarding fair and quick responses to serious defects

We understand that it is our responsibility to make our best effort to ensure that defects do not occur in the products, and at the same time it is also our responsibility to prepare for emergencies in the building of powertrains, which are a complex industrial product. JATCO's basic position is to mount a transparent, fair, and quick response. Specifically, we give top priority to ensuring the safety of our customers, minimizing inconvenience to them, and complying with laws and regulations, which leads to quick repairs.

Initiatives with partners

JATCO works together with our partners to tackle quality enhancement in all of the production bases from the component design stage, including the risk response concerning the quality and supply of the components.

Management of risk evaluation and reduction promoted with our partners

We are strengthening global quality management, confirming the quality management status of the production processes in each of the bases of our partners on-site and with the actual products, and supporting the improvement activities of our partners so that they can satisfy the JATCO's required levels.

Furthermore, we are working on a variety of quality enhancement measures such as carrying out joint improvement activities which involve not only our partners who deliver components to JATCO but also the secondary partners who produce the constituent components of those components.

Auditing and training for product safety and quality enhancement

In order to ensure product safety, JATCO works together with our partners to implement audits of not only the products but also the delivered components.

A variety of processes are necessary before one component is delivered from a partner to JATCO, from the confirmations of the planning stage to production of design drawings, construction of prototypes, checks of performance, ensuring the system of mass production, among others. JATCO has stipulated the quality assurance activities necessary in this series of steps as the quality management standards for its business partners, and has put in place mechanisms to ensure that accurate components are delivered by executing these activities for all of the components, one by one.

JATCO is supporting partners who are compliant with the Partner Health Check, which is JATCO's own partner quality evaluation standard. We confirm the worksites of our partners, including confirmation of whether or not there are clear identification methods for good products and defective products, and mechanisms for trouble prevention, etc.

Furthermore, we use a quality management system in collaboration with our partners to confirm that materials certification has been acquired for all of the components with regards to not only the manufacturing processes but also the materials of the components. We have built a system which ensures that accurate components are delivered by implementing training about the quality management standards for business partners in all of our partners and rolling out and executing the standards inside our partners.

Furthermore, we are implementing diagnoses of delivery quality and market quality, etc., using the partner scorecard, and we are also implementing partner plant audits to confirm management systems. Through these diagnoses and audits, we are regularly confirming the mechanisms for the stable supply of good quality components and the implementation status of continuous quality improvement activities.

Enhancement of “service quality”

JATCO is working on optimization of inspection and repair methods. Specifically, we are providing quick, cheap, and reliable repair methods such as alleviation of the customer burden by keeping replacement components to a minimum, alleviation of the repair burden of dealers by optimizing inspection and repair methods, etc.