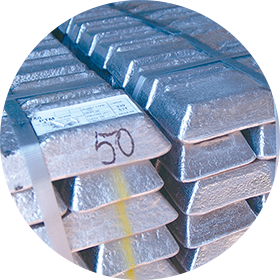

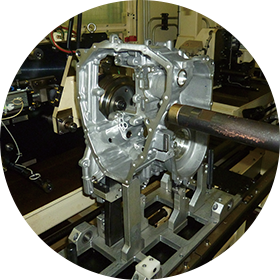

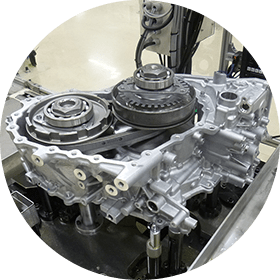

Forging

The process of "adding force to change the shape of objects" is referred to as plasticity forming. Among plasticity forming methods, "forging" in which parts are made by pressing materials into a mold using strong force, possesses the attribute of producing highly durable parts.

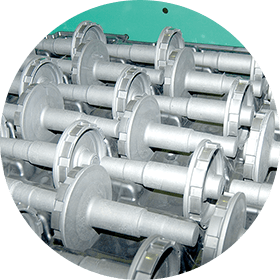

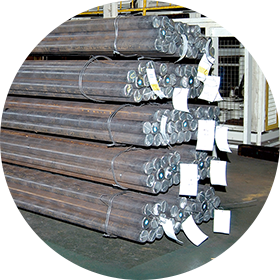

Steel material

Cylindrical steel pieces

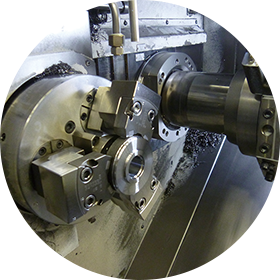

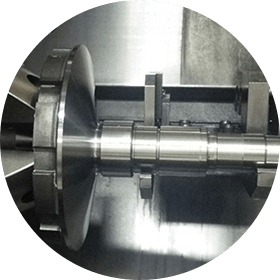

Cutting

Material is cut to length

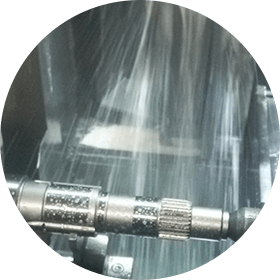

Heating

Heating prior to forging

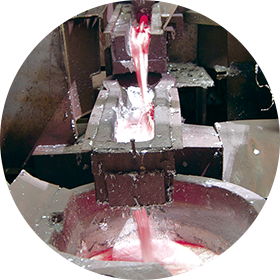

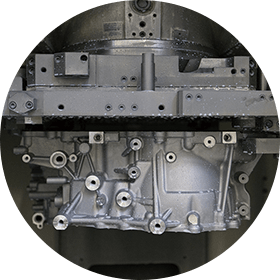

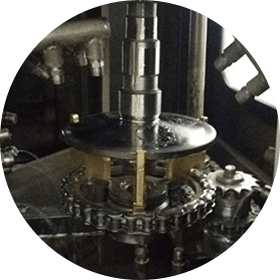

Forging

Stamping to shape

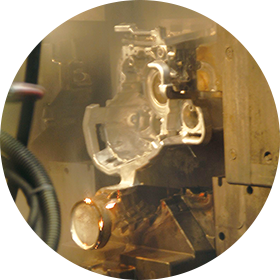

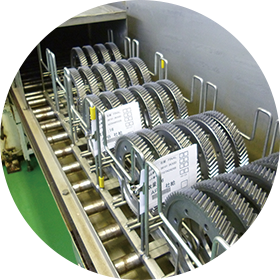

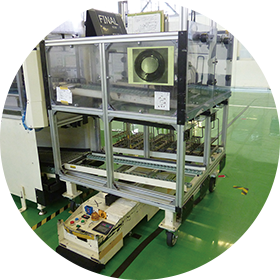

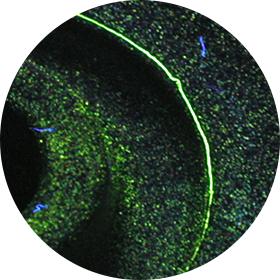

Magnetic Particle Testing

Inspection for scratches, cracks

Exterior check