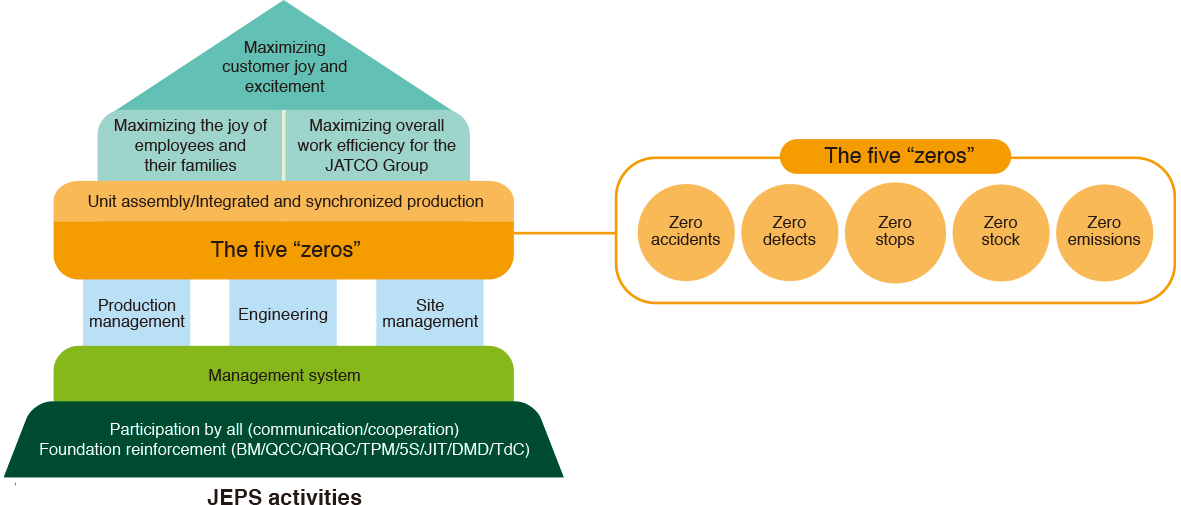

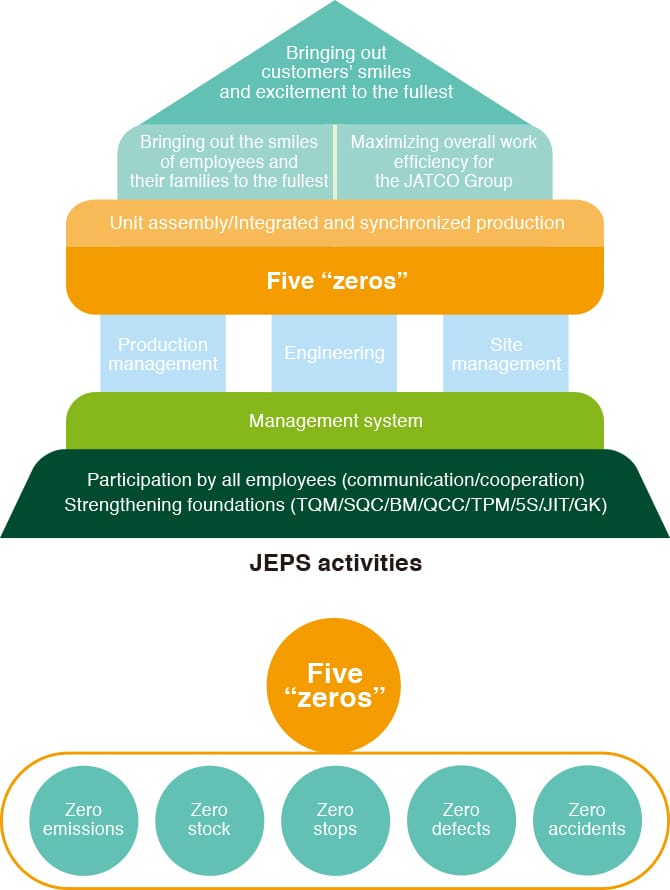

JEPS (JATCO Excellent Production System)

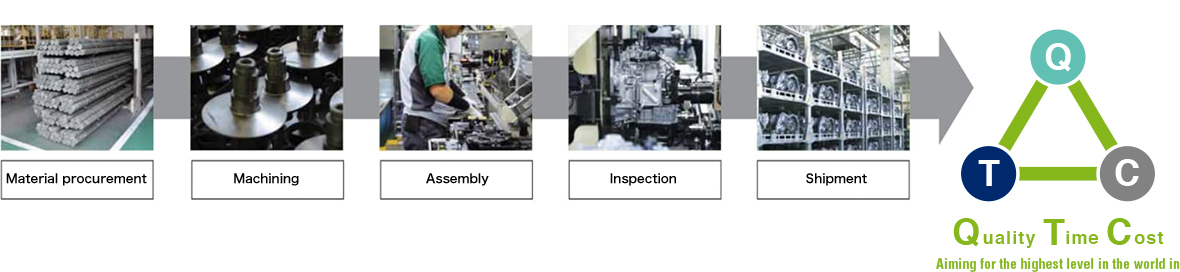

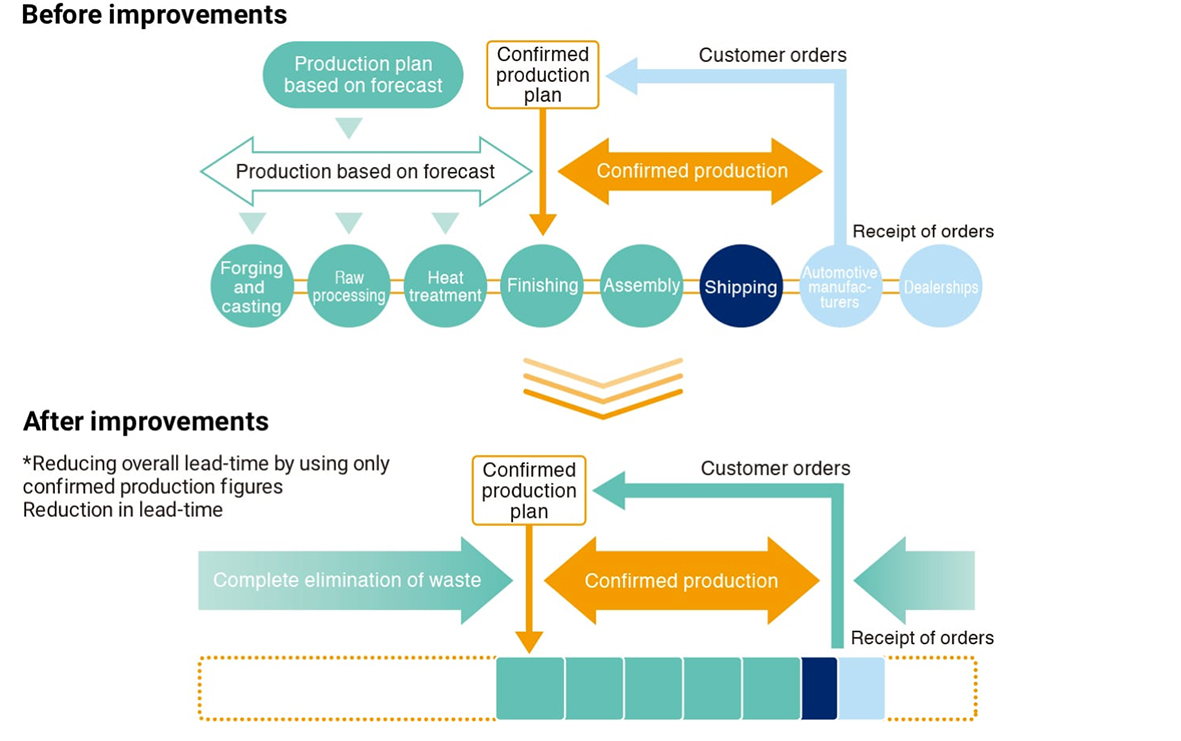

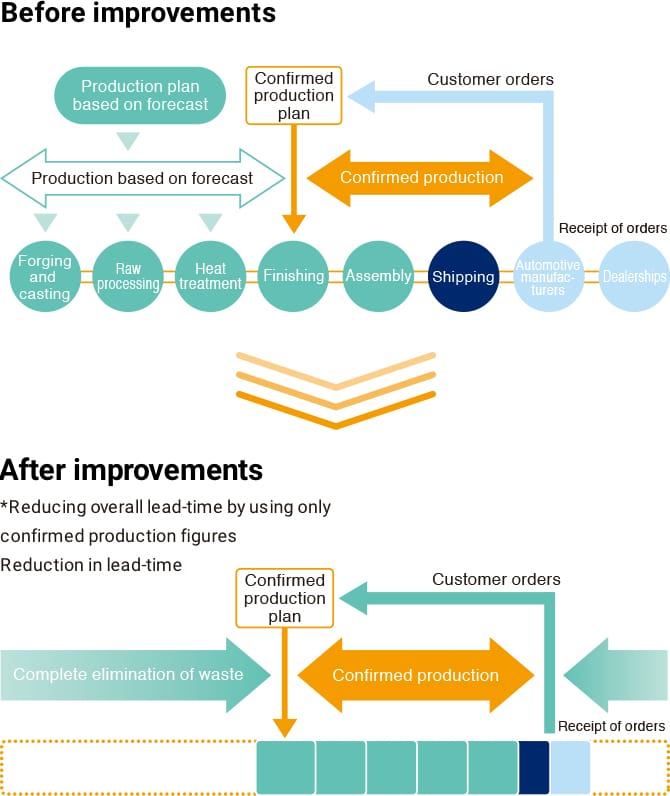

JATCO's unique production system, JEPS, responds flexibly to changing market needs and achieves the highest level of monozukuri excellence in the World in all aspects of quality, time, and cost. JEPS eliminates the waste completely by synchronizing the operations in each process-from the procurement of materials, machining, assembly, inspection, to shipment-as if they were carried out on a single line.

Promoting JEPS innovation

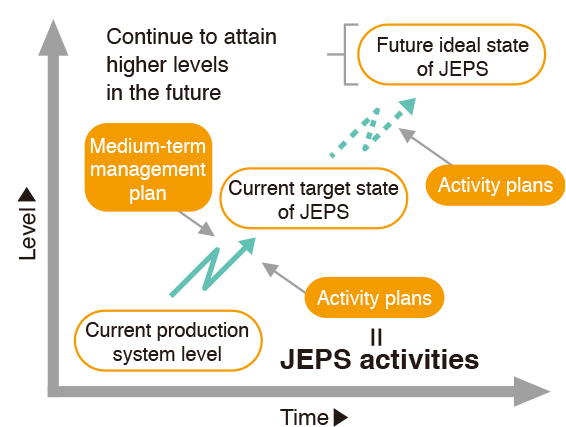

The basic stance of JEPS can be summed up into the following two points: unlimited synchronization with our customers, and visualization of unlimited challenge and innovation. To pursue these two “unlimited goals,” JATCO has established clear indicators in the form of the five “zeros.” Toward the achievement of these goals, JATCO continuously improves JEPS and promotes energy and resource conservation.

The two “unlimiteds” initiatives

1. Unlimited synchronization with our customers

Q : Quality synchronization – producing the quality demanded by our customers

T : Time synchronization – Reducing production lead time to get as close to the customer as possible

C : Cost synchronization – Increasing added value that customers are willing to pay for.

JATCO aims to pursue these three synchronizations to move infinitely closer to our customers.

2. Unlimited innovation and realization of challenges

While recognizing the gap between our current state and the ideal state that JATCO should strive for as the world’s no. 1 in monozukuri, we are striving to make visible the challenges we have had difficulty admitting to. We are continuously trying to improve our monozukuri system through repeated improvements and innovation.

Skill Transferance

The essential skills of manufacturing have been handed down from person to person at our in-house training school, now renamed the Global Training Center (GTC). To this day, JATCO’s unique expertise continues to be preserved and transmitted at the GTC.