Press releases

JATCO develops a new wet clutch using biomimetics

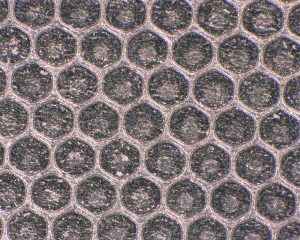

JATCO has developed a new surface machining technology that enables both improved frictional characteristics and durability for wet clutches, which are used to transmit motive power in a vehicle’s transmission. This new technology takes inspiration from the hexagonal microstructures arrayed on the base of the feet of two animals: frogs and katydids. By performing special machining that increases oil-draining performance to the surface of the steel plates※1 in a clutch, the stability of the frictional characteristics and the durability can be greatly improved.

JATCO has manufactured over 120 million AT/CVT units as an automatic transmission manufacturer. We have cultivated our machining technologies for parts that transmit motive power, such as gears and clutches, and will continue to evolve these technologies for the coming age of electrified vehicles.

The surface machining technology we have developed this time is rare among biomimetic technologies for being inspired by two types of animals. Katydid feet have the ability to suppress the stick-slip phenomenon※2 on contact surfaces to produce steady friction, while frogs have the ability to grip wet surfaces. By machining the hexagonal shape common to both animals onto the steel plate side of a clutch, we can increase the stability of torque transmission at low temperatures and increase the durability of the clutch. Furthermore, to prepare for mass production, we are carrying out joint development with Tokuhatsu Co., Ltd., which possesses micro press technology.

To date, improvements in clutch performance have mostly been focused on enhancing the performance of the friction materials on the facing plate side, but clutch performance can be further increased by applying surface machining to the steel plate side. Experimentation internally has shown a large improvement in both durability and friction characteristics.

We are not only considering the adoption of this wet clutch using biomimetics in our AT/CVT units and e-Axle for electrified vehicles, but also evaluating its use in a wide variety of mobility-related products.

※1 A wet multi-plate clutch for automobiles consists of alternating metal plates, with one being a steel plate, and the other being a facing plate, which has friction materials bonded to it.

※2 A vibration phenomenon caused by alternation between a state resulting from static friction and a state resulting from kinetic friction.